Error

Message

|

Problem |

Solution |

001 EMERGENCY STOP ACTIVE |

E-stop

pushed in. |

Release E-stop, and click E-stop release on screen. |

001 EMERGENCY STOP ACTIVE and 042 AXIS ON OVERTRAVEL LIMIT |

Machine suddenly stopped in the middle of a cut and displayed 2 error messages. |

|

010 CAUTION! OVERTRAVEL LIMIT ACTIVE |

G-code file will go beyond the table size if run. |

Adjust working origin. Redo G-code file to correct size. |

011 AXES NOT REFERENCED |

Machine has not been homed. |

Press Home All on screen. |

013 MPG ENABLED |

Handwheel is active. |

Click on Auto or Continuous to deactivate handwheel. |

022 Warning! temporary spindle stop |

Spindle will not turn on. |

Can be a result of a bad relay. Generally the third relay from the left. 10-series has O28 on it, open series has 029. |

034 AXIS DRIVES FAULT |

One of the axis amps shut down. |

Cycle power on and off to reset amp. Check cables going to Amp. |

041 SPINDLE INVERTER 1 FAULT |

Spindle had a fault and shut down. |

Cycle power on and off to restart inverter. |

042 AXIS ON OVERTRAVEL LIMIT |

The over travel limit switch has been triggered. |

Slowly jog machine away from end of gantry. Check limit switches for debris. |

088 Spindle 1 stopped fault |

Spindle will not turn on. |

Can be a result of a bad relay. Generally the third relay from the left. 10-series has O28 on it, open series has 029. |

089 Zone A intrusion sensor tripped |

The safety interlock has been triggered during the cut cycle. |

Exit safe zone, reset controller, and restart program. |

090 Zone B intrusion sensor tripped |

The safety interlock has been triggered during the cut cycle. |

Exit safe zone, reset controller, and restart program. |

22/60 or 22/61 Error Pass Positive/Negative Limit |

|

|

HD001 File configuration not found

SYSTEM STOPPED

|

A file in the Osai controller has been corrupted. |

Contact Techno immediately upon seeing this error. An Osai system restore will be necessary. NOTE: This error has nothing to do with the computer. |

NC030 Circle is not

Congruent. Dynamic mode

not Congruent. |

G-code file has an

incorrect arc |

Arcs must be absolute

i’s and j’s, or created using R. Select one of these options in the

CAM post processor. |

NC101 Process 1

Positive over Travel |

The G-code file is

trying to run beyond

the table size. |

Adjust Origin Redo G-code File |

NC123

Bad Cycle Mode |

Tried to press Cycle

start to run file. |

Hold is active, press

hold to release, select

Auto, press Cycle

Start. |

VFD Error CF 3.6 or HPF |

Check incoming power. |

Must be 208 - 230 V |

Fig. 1 |

Problem |

Solution |

|

Dust collector hose is arcing to your dust hood.

|

Check that your dust collector flex hose and metal ducting are properly grounded to the ground rod. |

Problem |

Solution |

During the Homing process, the machine will make contact with the limit switches then back off and continue to slowly move in the opposite direction without stopping. |

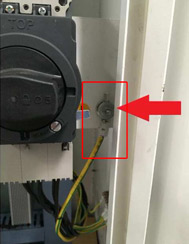

There are loose input wires inside of the controller cabinet. |

| HDS Touch Off Location - HDS change the touch off location |

To change the touch off location, do the following:

|

| HDS Machine Freezes during Tool change, or when it tries to do a tool change in a g-code file. |

This error can occur if the pneumatic sensor on the dust shroud is faulty.

|

| Machine Stops during tool changes, stops at unlock drawbar in g-code macro. |

|

| HDS Problem: Tool cuts deeper than it's suppose to |

Possible solutions:

|

| Syntax Error when loading a g-code file. |

| There is an unrecognized command in the g-code file. Use the correct Techno post in the CAM package and output the file again. |

| If the HDS machine gets a 'skew error': |

| If the HDS machine gets a servo error: EE001 Process: 1 Servo error axis X A servo error would suggest that the motor encountered enough resistance to basically trip the breaker on the amplifier. The machine will not home. |

|

|

| Let Techno know if you see the error again. |

|