The toolchanger sensors detect the state the toolchanger is in so safe

toolchanges can be performed.

If the sensors fail or are misaligned, the toolchanger

will freeze.

To test the sensors, first, determine

which spindle you have

HSD (Common on new machines) toolchanger sensor testing:

- Lock

out power from the spindle, but leave the machine enabled.

- Remove air pressure from the machine

- Remove the two air hoses that run into the spindle

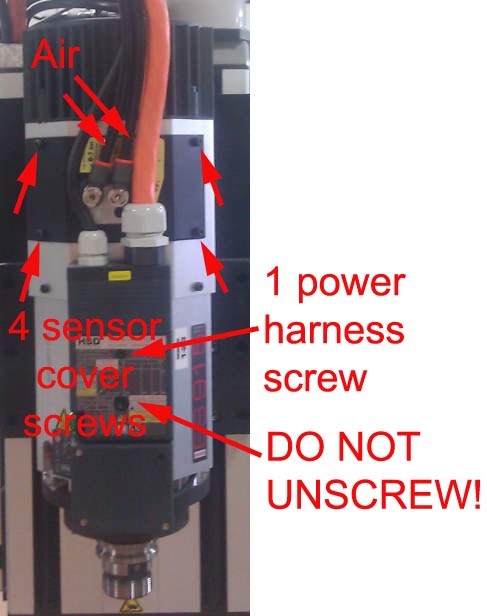

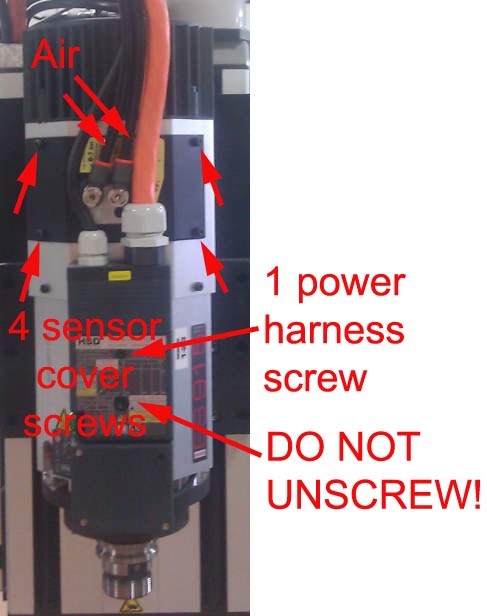

- Remove the screw that holds the power cables in place

- Remove the power and sensor connection

- Remove the 4 sensor cover screws and the sensor cover

- Put the power cable harness back in place

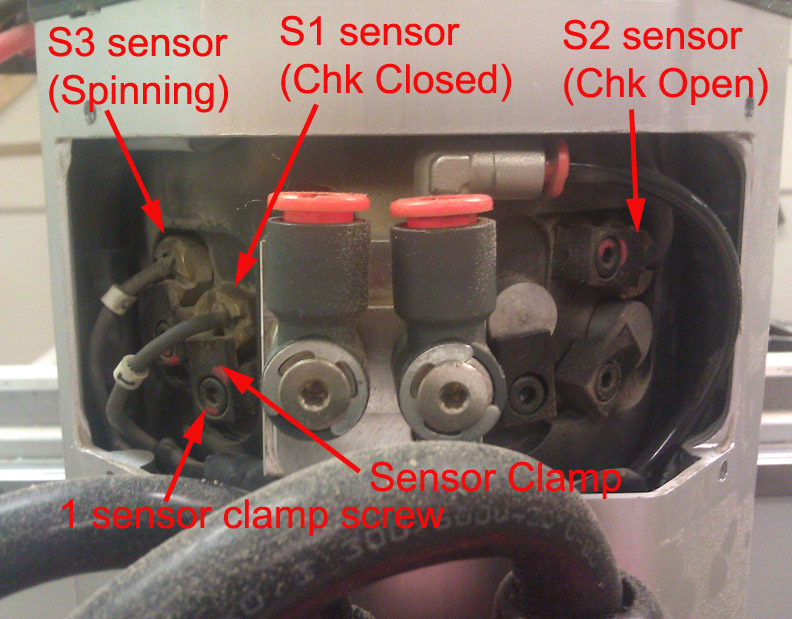

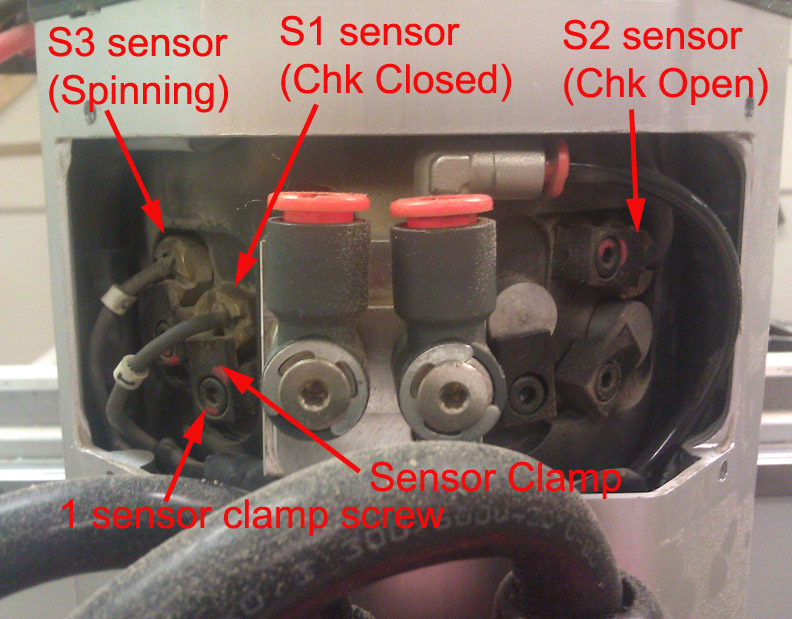

- S1 is the sensor for Chuck Closed

- S2 is the sensor for Chuck Open

- S3 is the sensor for spindle running

Unscrew the sensor clamp, remove the sensor and test it in

Setup->diagnostics by putting a piece of steel up to the tip and verifying

response.

If there is no response on only one sensor and all other sensors work

properly, the sensor likely needs to be replaced. Contact HSD USA to obtain a replacement.

If the sensor checks out properly in diagnostics, it is probably just

misaligned in the housing.

- Notice how the sensor body is not concentric with the holder body. As you

rotate the sensor in the spindle, the position of the sensor will change.

- While watching diagnostics, rotate the sensor until the proper response

is obtained, then tighten down the sensor.

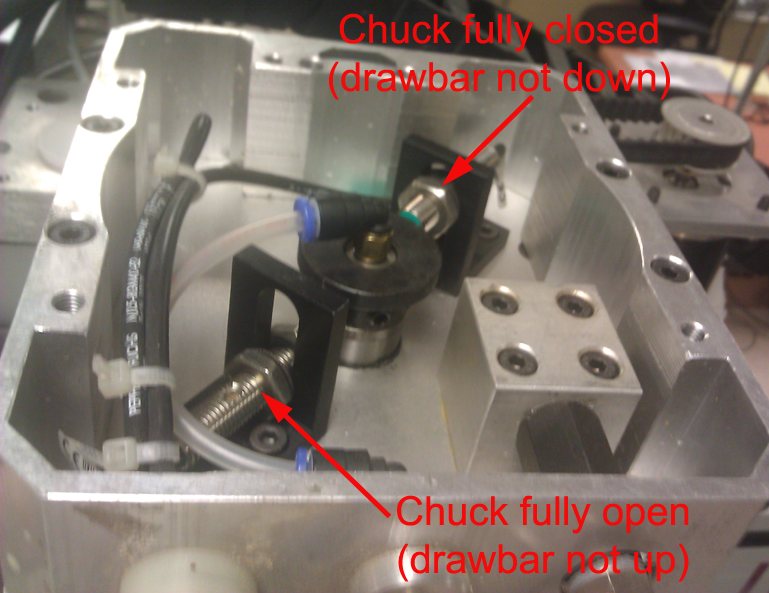

Note that the spindle must be in the proper state (chuck open/closed) for

the sensor to properly sense the state. This means that if you are testing the

chuck closed sensor, the chuck must be closed and there must be a tool in the

chuck or the sensor will never trip, no matter how good it is or where it is

located.

Columbo (Less common on new machines) toolchanger sensor testing:

- Lock

out power from the spindle, leave the machine enabled.

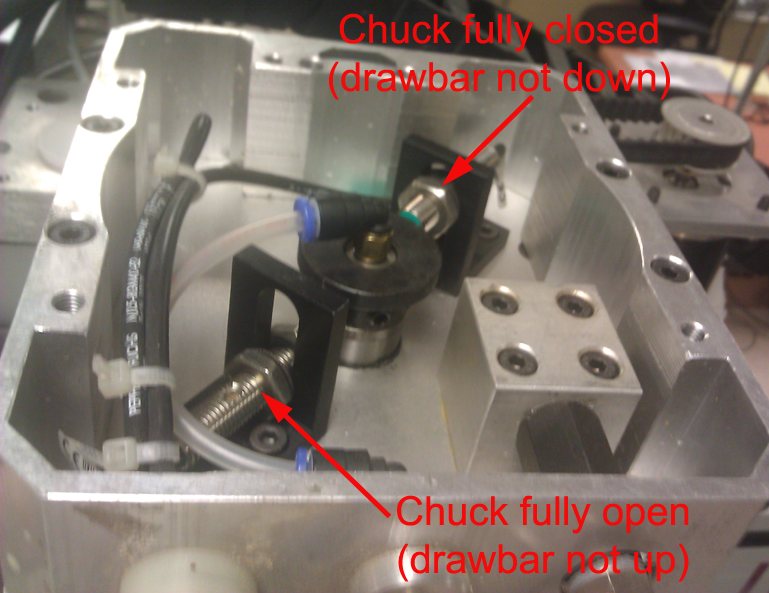

- Remove the 2 or 4 bolts from the top face (facing the sky) of the

spindle. This exposes the chuck sensors.

- Exercise the chuck to see how the mushroom head moves upwards and

downwards and trips the sensors.

- The top sensor is for chuck fully closed

- The bottom sensor is for chuck fully open

- If the top sensor (closed) seems too high, there is possibly dust/other

obstructions in the spindle. It should be cleaned -- moving the sensor is not

an acceptable repair in this situation.

Touch steel to the sensor and verify it responds in Setup->diagnostics.

If there is no response on only one sensor and all other sensors work

properly, the sensor likely needs to be replaced. Contact PDS Columbo to obtain a replacement. |