|

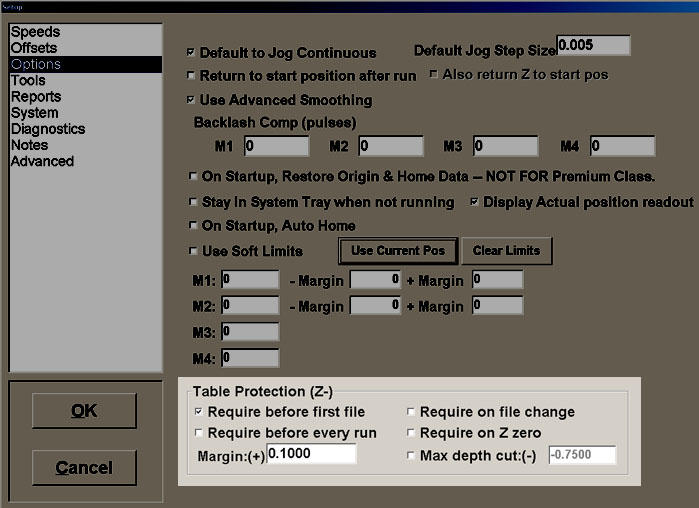

The Techno CNC Interface Version 1.424.1 and newer has functionality to help prevent users from accidentally cutting too deep and damaging the table. This functionality requires the user touch off on the table or MDF sacrifice surface to prevent cutting these surfaces. To employ this function, enter Setup, Options and select the modes you wish to use.

1)Require before first file - This mode will require a safety touchoff before the first file is run every time the CNC interface is started up. 2)Require before every run - This mode will require a safety touchoff before running every file. 3)Require on file change - This mode will require a safety touchoff every time the user selects a new file to run 4)Require on Z zero - This mode will require a safety touchoff every time the user re-zeroes the Z axis The user may also perform a safety touchoff if none of the modes are selected. The distances will be checked before running. The only difference is that when one or more of the modes are checked, the system will require a safety touchoff, whereas when none of the modes are checked, it is simply optional.

If the user wishes to restrict cut depth, enter a negative value. For instance, if touching off on the table surface, but employing 0.75" of MDF as a sacrifice board, enter -.735 to allow the system to cut into the MDF board by .015" Max depth cut(-) - This functionality is separate from the safety touchoff but is for similar purposes. The value put into the text box next to the check box represents the maximum Z negative depth allowed in a file, regardless of Z zero position or table protection position. If the file trajectory will lead past this value, an error will be presented. This feature can be used in combination with the others and prevents "slips of the decimal point", where an intended value of -.75 is accidentally made 75. by typographical error.

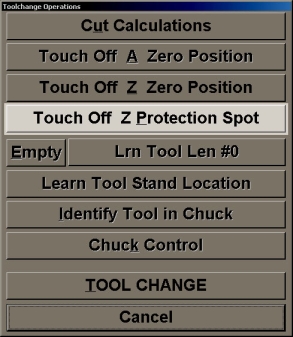

1)Place the touchpad on the surface that should not be cut (or only cut slightly, if the margin is in use) 2)Hover the cutter over the touchpad 3) Click Tools 4)Click "Touch off Z Protection Spot" as shown below:

This functionality is not a substitute for common sense, nor is it able to protect the table in all circumstances. If the user does the following, this functionality will not be effective: 1)Reloads a new cutter and does not perform another safety touchoff. (The system will track automatic toolchanging across properly learned and identified tools, but can do nothing to help misidentified or mislearned or manually loaded tools). Therefore, on manual collet spindles, it is best to perform a safety touchoff after changing tools, in addition to touching off Z zero again. 2)Performs a safety touchoff on the wrong surface As always, a trained user focusing only on the project and the safety of the situation is a requirement. No software or safety feature is a substitute for a professional, experienced machine operator. |

Copyright ©

Techno CNC Systems, LLC. All rights reserved.